Norton 2

Not satisfied with one Commando, I now have a potential second one... if my mechanical skills get me there.

Not satisfied with one Commando, I now have a potential second one... if my mechanical skills get me there.

I purchased it a month ago from Mark Upham at British Only in Pettendorf, Ober Österreich. Mark has quite a beautiful place in the countryside and a booming mail order business for vintage bikes. I had been watching videos of people restoring old bikes and decided to give it a go as a winter project.

There are many parts missing: all the electrics, carbs, handlebars, side panels, battery tray, etc. But all are available at a price. I will be looking out for second-hand items too, or maybe even another project bike for spares.

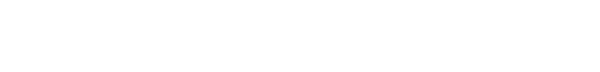

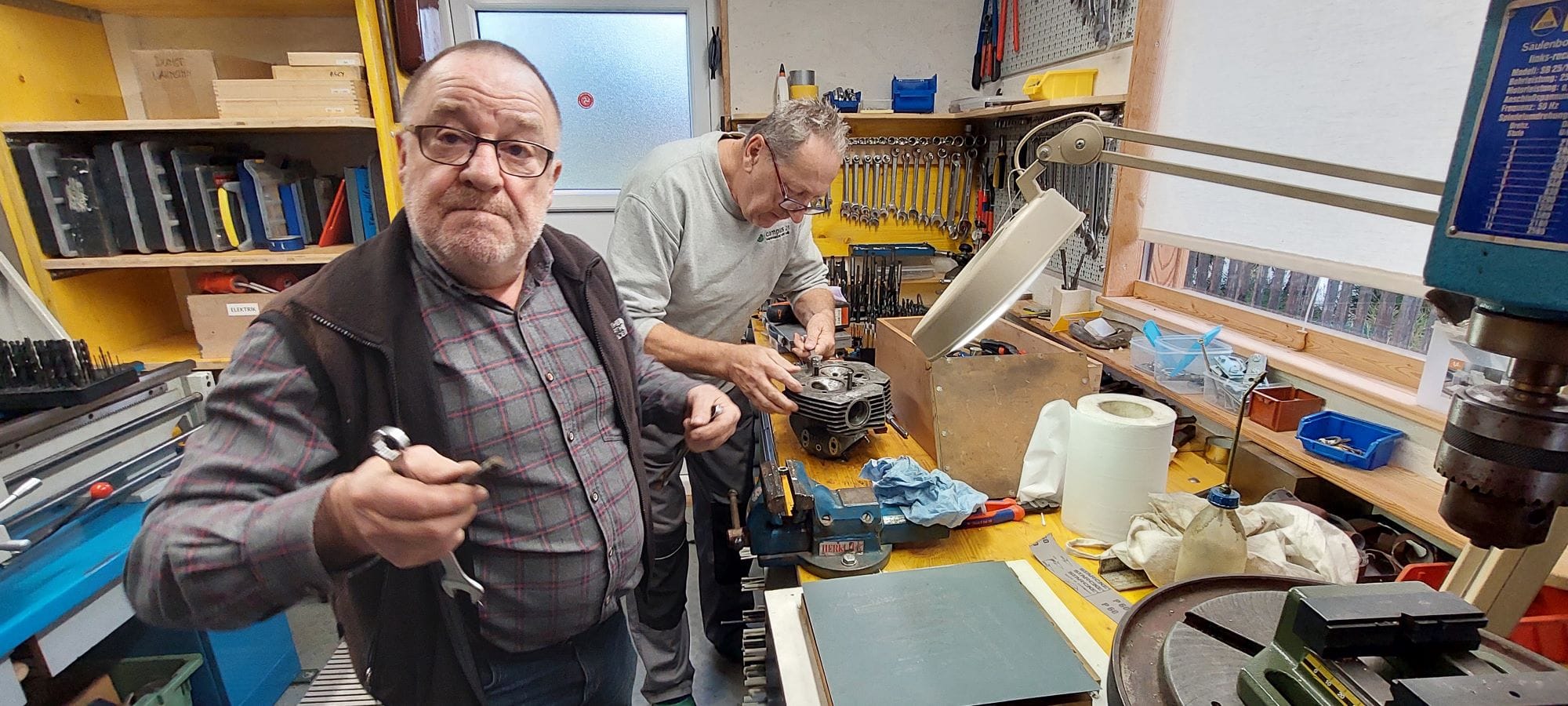

There's not much room in the garage and no light or heat. The plan is to store the Mini elsewhere and build a workbench and maybe buy a pneumatic bike lift. In the mean time I built a stand for the motor and started dismantling the cylinder head, but am stuck due to lack of 1/4 inch narrow Whitworth socket for the front head bolts.

Day 1

After a wait for all the correct spanners, specifically the 1/4" Whitworth with 3/8" drive that fits into the head, I managed to get the head off. Not surprised at the state of it:

Day 2

Got a workbench in place which makes things easier on the back.

Bought a valve spring compressor and got the exhaust valves out, but couldn't do the inlet ones until I got rid of the post that holds the cover in place. Thread is metric for some reason.

Had to drift out one of the valves, then read later that I shouldn't have - should first have filed the stem so as not to score the valve guides. Valve guide replacement required another special tool and I am not sure I am capable of that.

Once I got the valves out I spent some time cleaning the head. I have no idea if these valve seats are good or not. Still got a broken off spark plug on one side.

Day 3

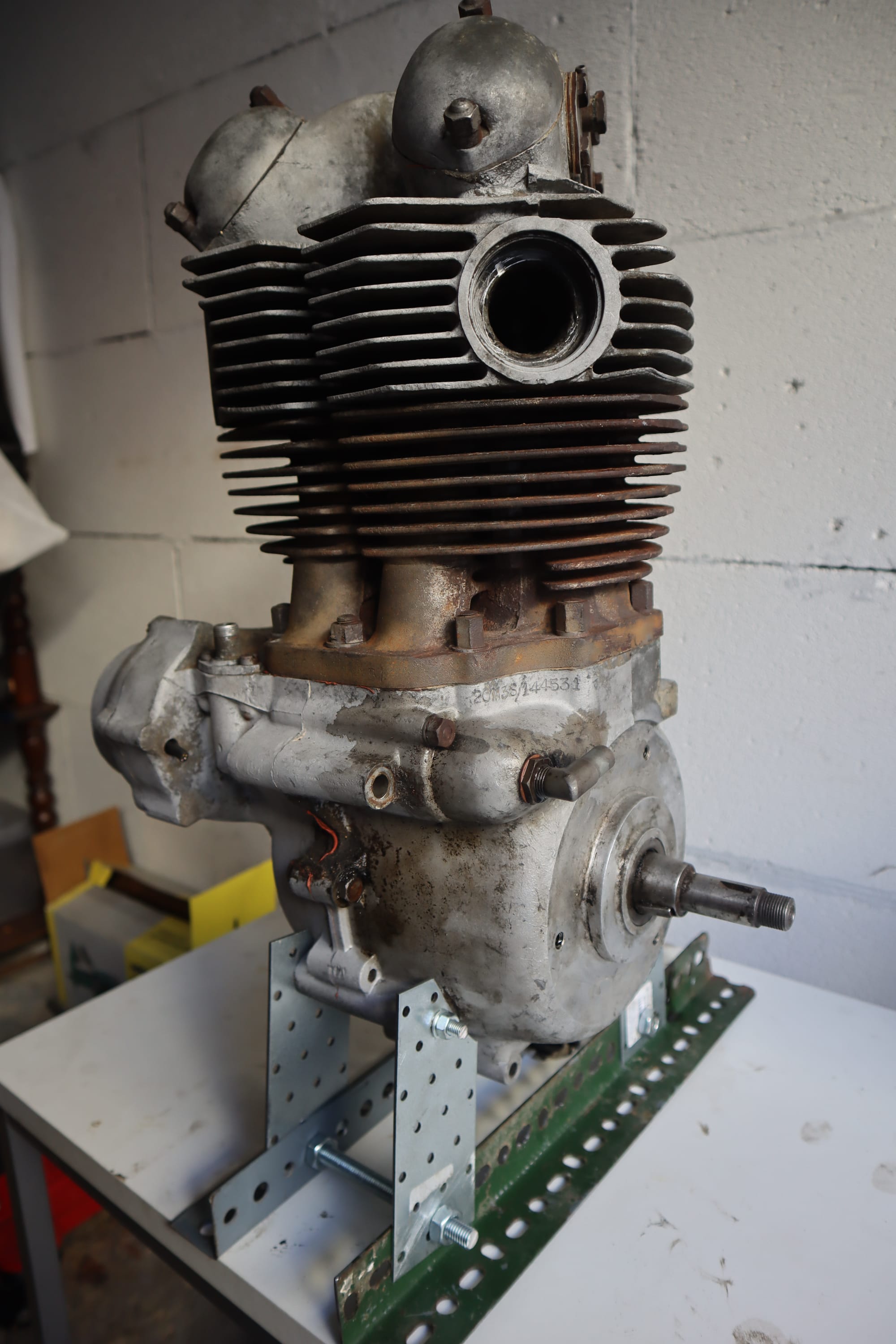

Found these guys to help getting the broken plug out. Even though we failed it was a great effort and I learned something. Christian, on the left, has about 20 pre-1960s bikes in his shed.

The rocker spindle extractor arrived and I set it to work. A bit of heat required, but all came out fine-ish.

Made first attempt at getting the barrels off, but the pistons are really glued in. Though that gravity might help overnight.

Finally realised that only heat and violence would work and after much beating with a stick I got it off.

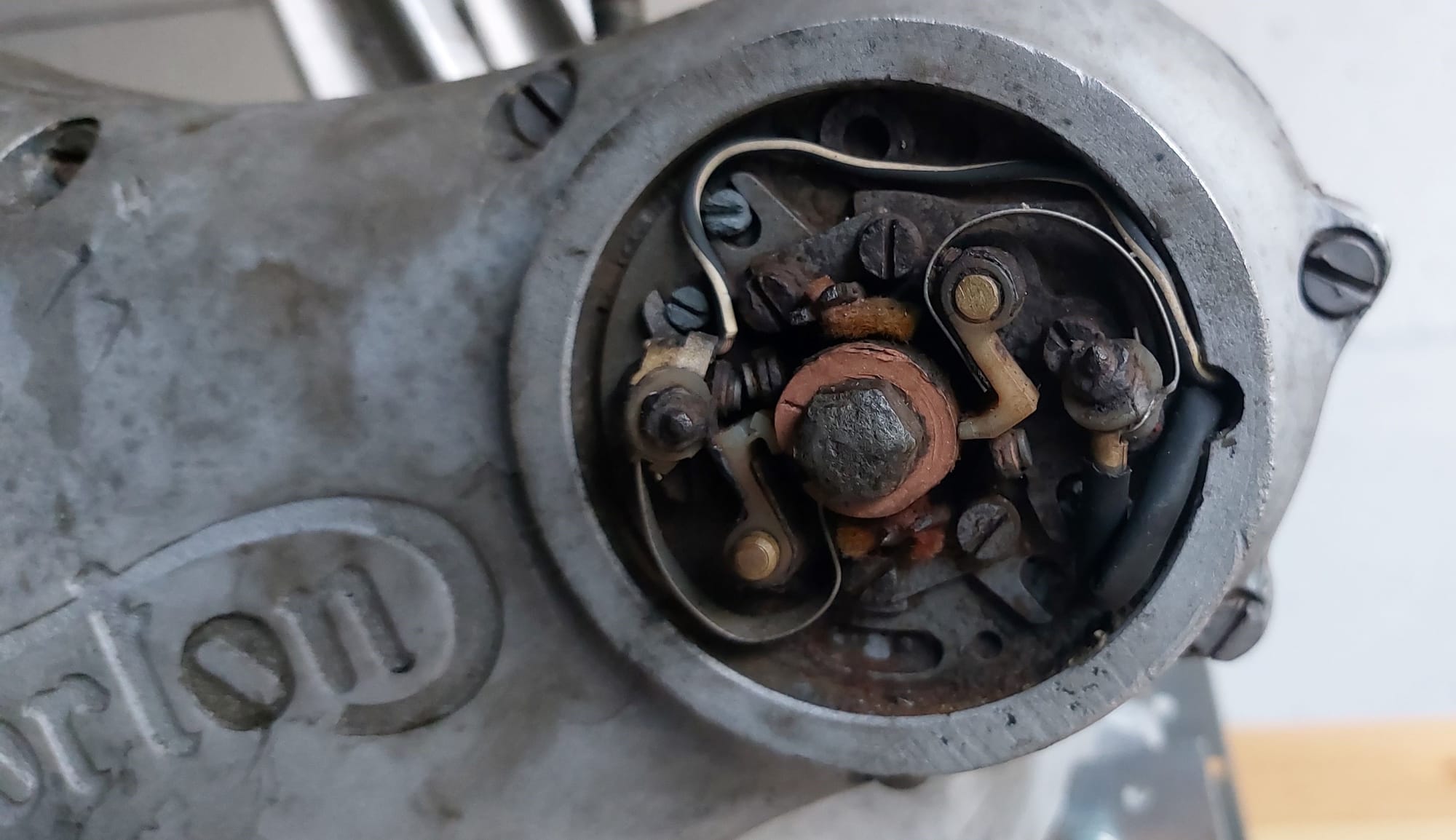

Then I set about getting the timing cover off, starting with the points.

Won't be reusing them

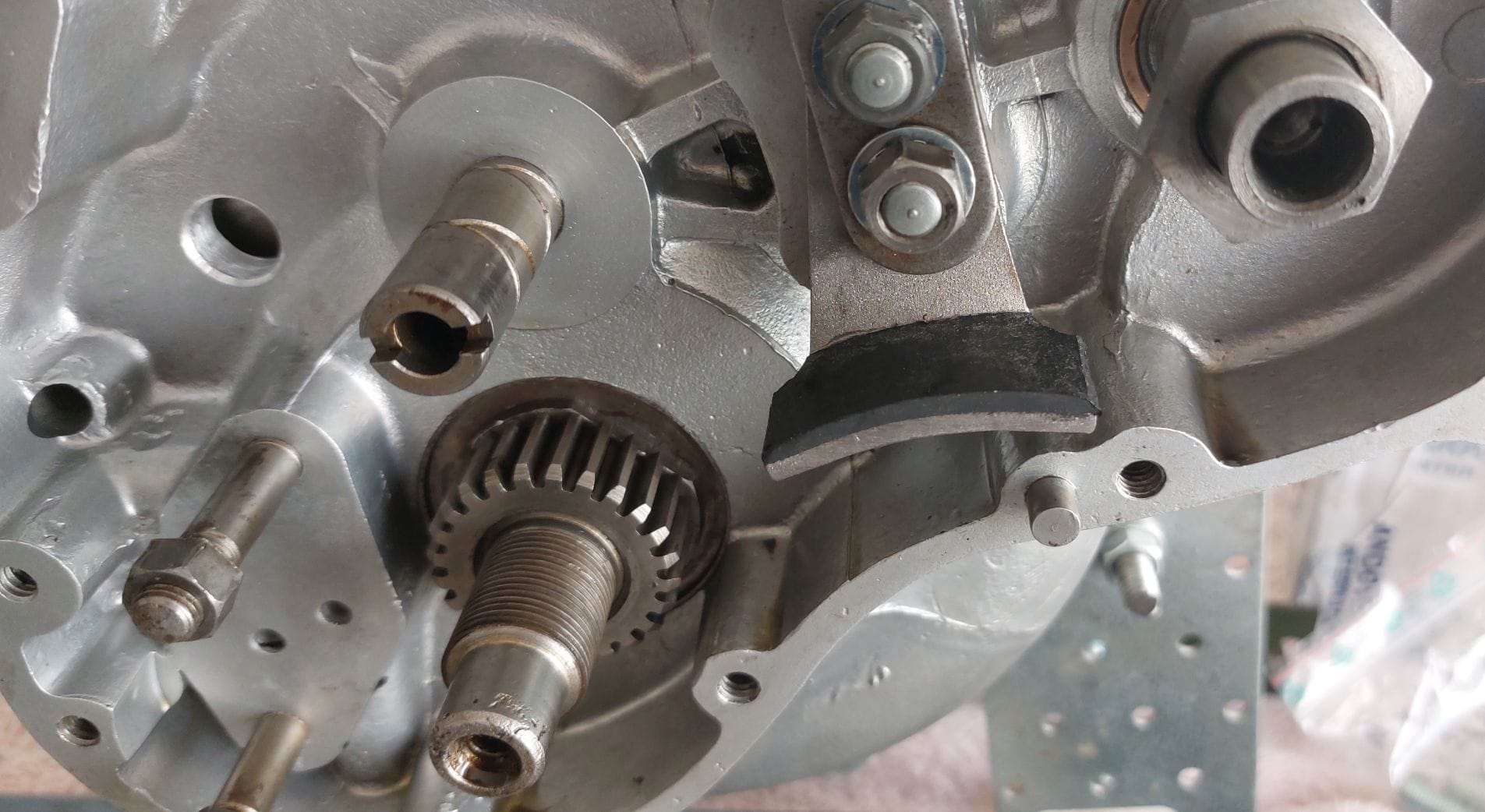

Got the timing cover off reasonably easily, then the worm gear and the oil pump. Plenty gunge and even insects in there.

But I am now stuck as I can't get the camshaft nut off. Will try more leverage tomorrow.

Day 4

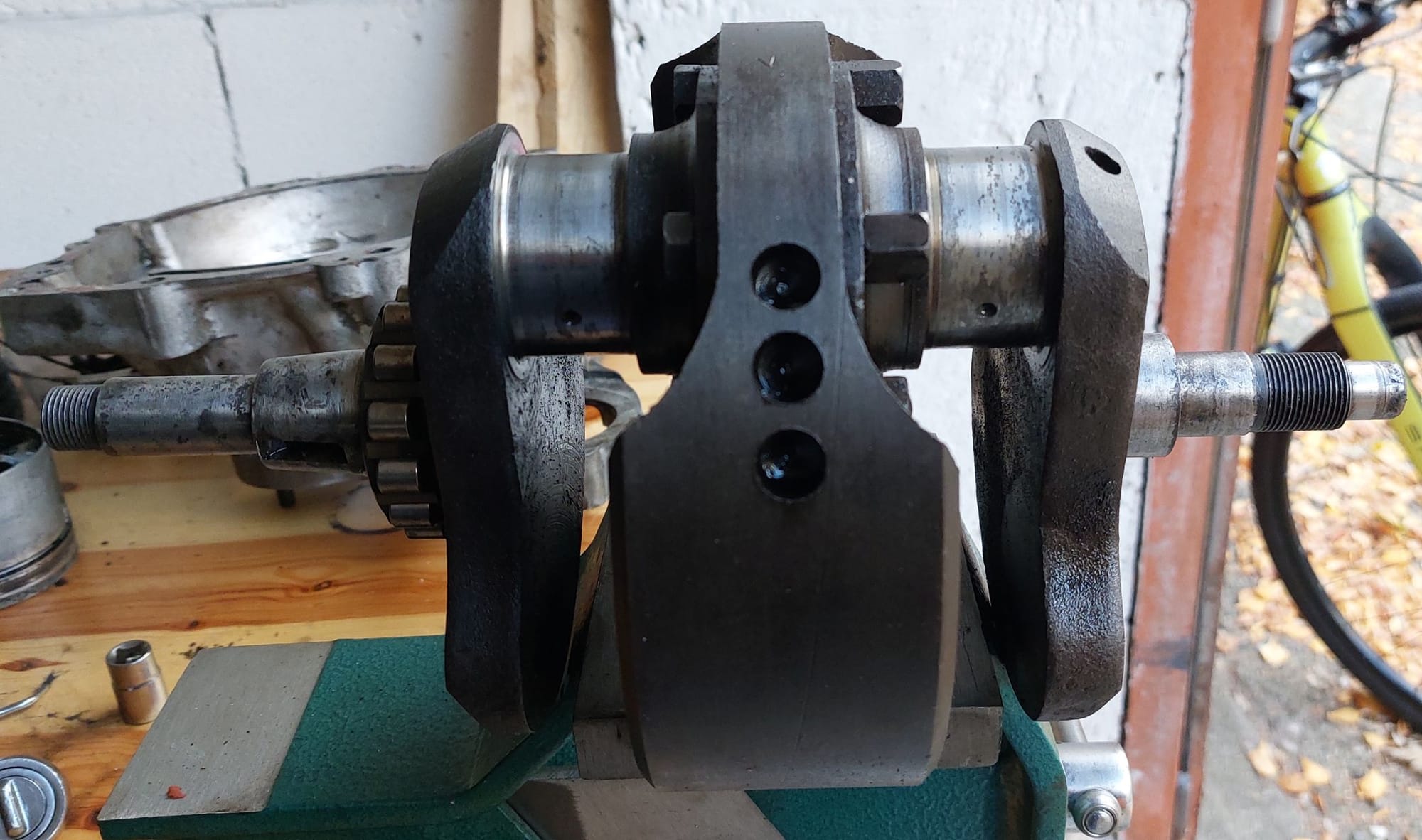

Got the nut off using an old fork stanchion as a lever. Then got the crank shaft out and took all apart. The big ends will probably need grinding. They are already at -10 thou. Everything now at my Mini mechanic getting sand- and vapour-blasted.

Day 5

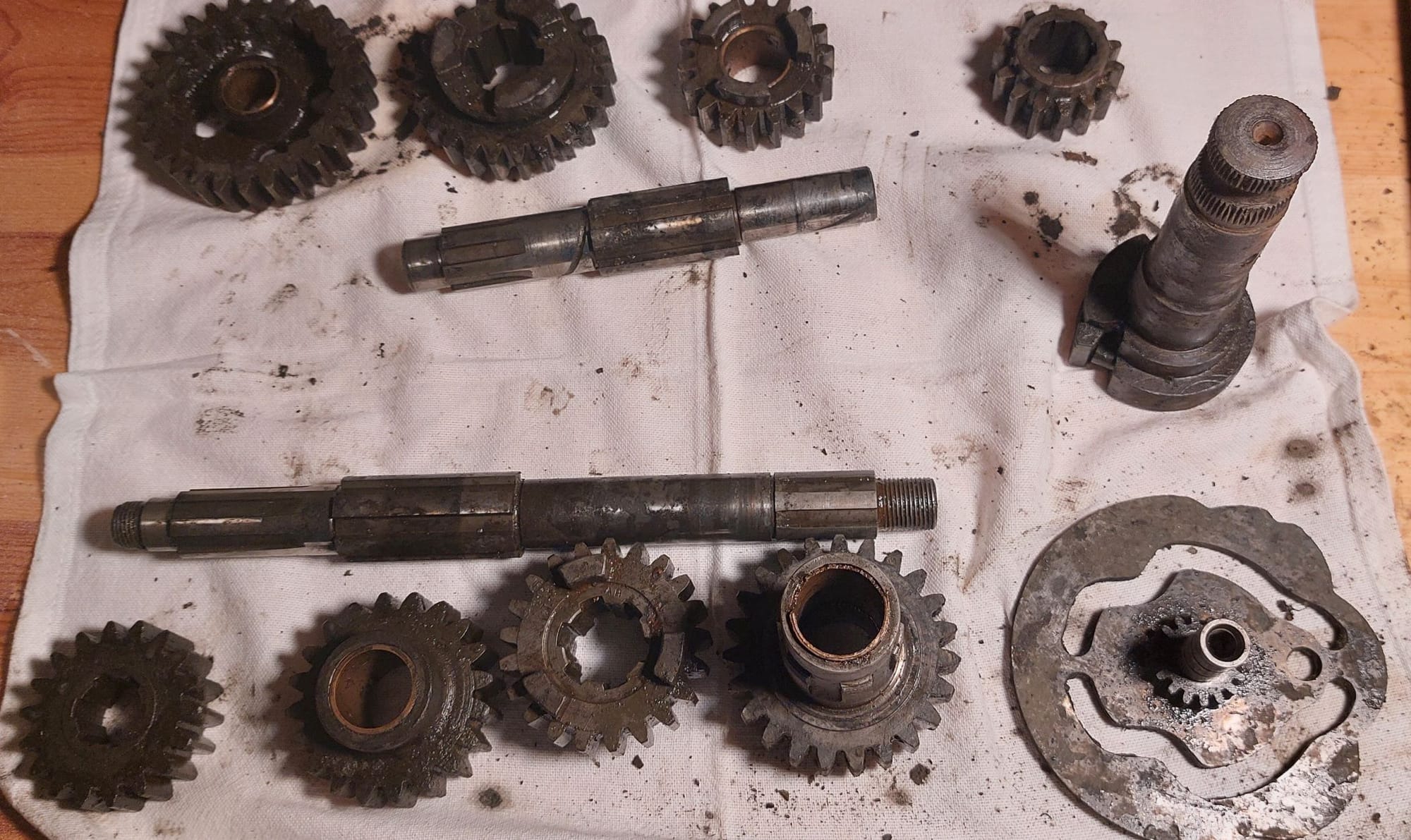

Started attacking the gearbox today. It's not so easy given I have just had an operation on my right hand. Still got stitches in so need to be careful. But, goodness me what a mess is in there!

Day 6

Had to wait for special tools (lockring nut and mainshaft locking spanner) to get the rest of the gearbox dismantled. It was like wrestling with an asymmetric rugby ball on the bench and floor getting the locknut then the mainshaft nut off. Could not be done without the 2 special tools.

I then needed another tool - a 1 1/4 inch socket to get the primary drive gear off. Had to make do with a large spanner as such a large socket seems impossible to get. Luckily it wasn't on too tight.

Finally heated the case to get all the gears and bearings out. But unfortunately most of the content is pretty corroded and unusable.

Day X - 3rd Feb 2025

It seems I've been waiting on others for a while now. The barrels and crankshaft have been with an engineering company since before Christmas. I finally drove down there last week to be told that the rust is too deep. They are currently +020 over and even +060 would not cut out the rust apparently. So I've ordered liners plus standard pistons, along with +020 big end shells.

I informed them that I'll bring them this week. Turns out they never saw all my previous emails. Don't know why.

In the meantime I thought I'd get the steering head started. I had to order a top yoke on eBay. Happily got these and some other parts powder coated, only to find the lower yoke is wildly bent.

So I am still waiting for a local chap to attempt to straighten them. He offered this about 4 weeks ago.

After getting these powder coated I was told that the head-steady had been welded and read that using it would be silly. An upgraded part exists. Would be wise to upgrade I think.

I received a gearbox from the guy that sold me the kit. Sadly it was from a fire sale in which the 86 year old owner died.

The internals are in good condition though. Although this is from a much older, pre-Commando bike, the internals looked fine, except the mainshaft which was shorter and different.

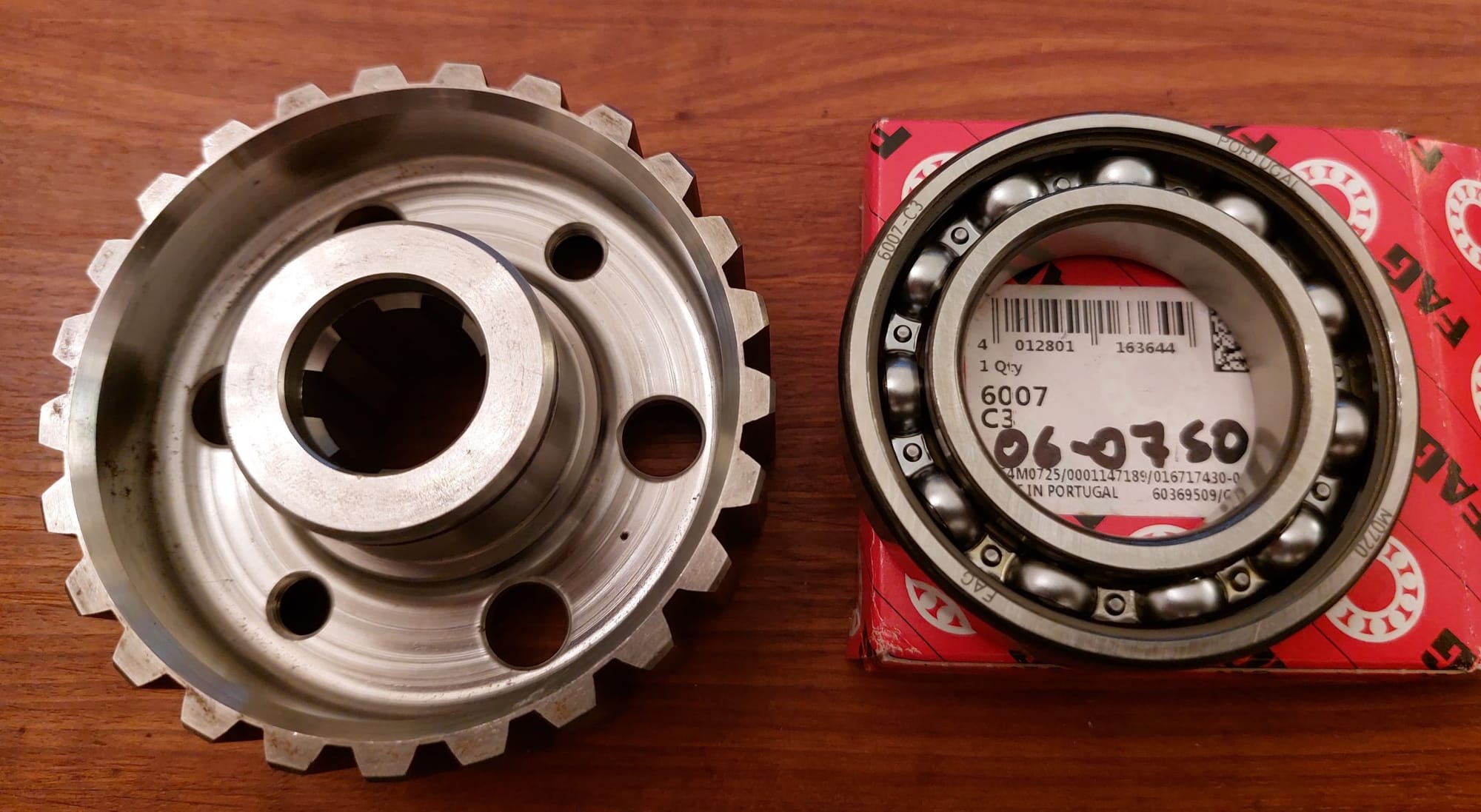

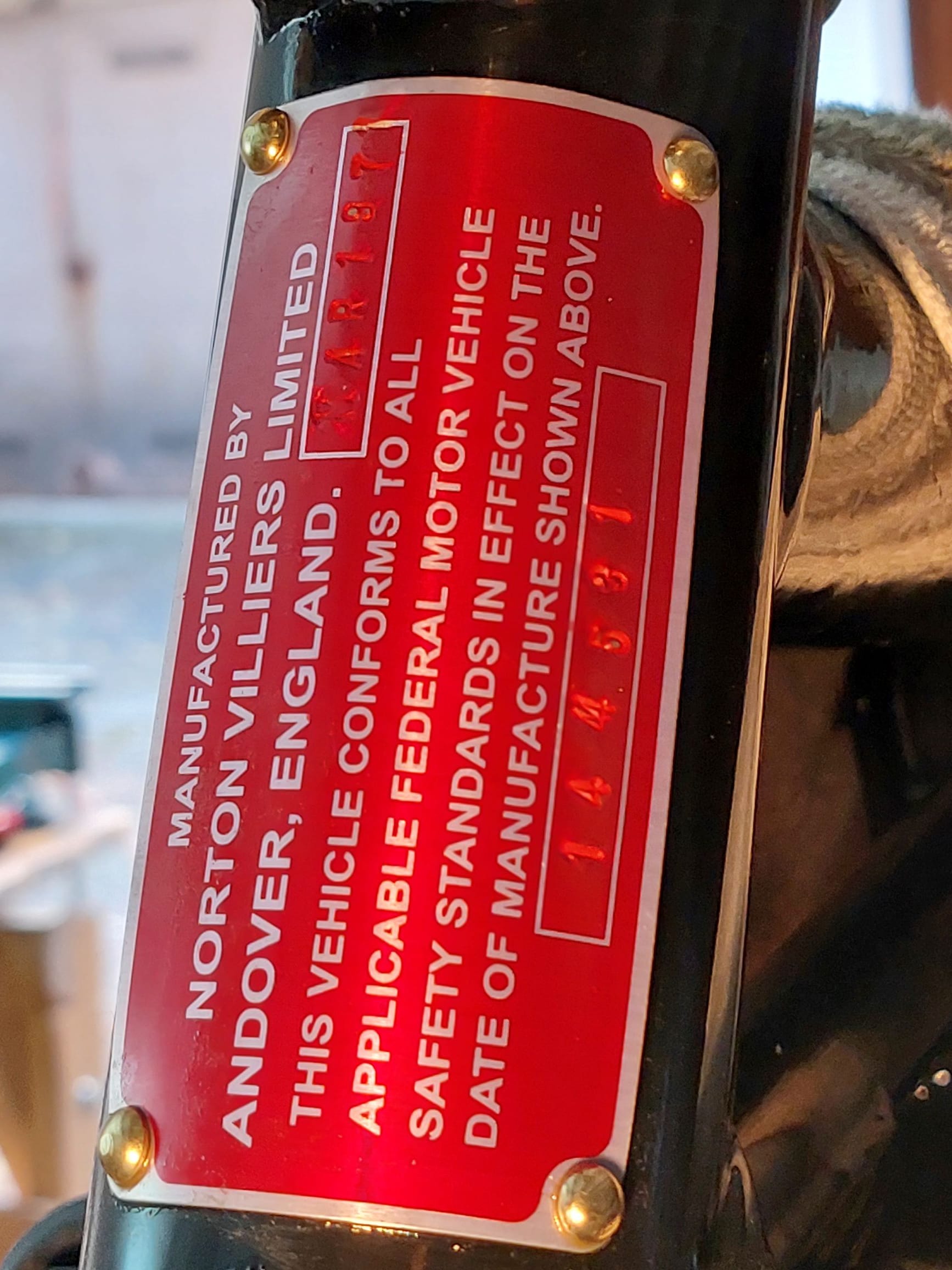

In the meantime I had ordered a box from eBay US. It took a couple of months to get here and I had to pay $150 transport and €100 import duty. The internals are fine-ish, except for 2 teeth missing on second gear! I fretted for ages about whether the pitting on the teeth were serious or not. I've decided to use them with a new pair of 2nd gears and will put the US box internals (14... quite close in origin to mine) in my original 144531 gearbox.

The main case has been destroyed though, which I was not told.

The layshaft bearing blind hole will need some attention.

So today, I put the new bearings into case. The mainshaft or sleeve drive bearing was a bit loose so I've added some Loktite. Might need it for the layshaft bearing too. We'll see if they still fall out with just a sharp tap of the box on some wood.

I've order new bushes for the sleeve drive too as it was a bit loose on the mainshaft, and a bush for the gear selector which was quite loose in the outer case.

So for now, I'm waiting for the lower yoke and frame, the cylinders/crankshaft, and for gearbox parts. Nothing happens quickly it would appear.

24th March 2025

Finally some progress:

The gearbox ended up needing new shafts as the old ones were bent. This was a costly adventure due to import duties, taxes and fees, and I ordered the wrong one! But with the help of a Norton guy, who reamed the sleeve gear bushes too, I got it back together.

The bottom yoke mentioned previously couldn't be straightened. I ended up buying a complete new MK3 frame from a guy on Willhaben complete with a top yoke (the MK3 requires different yokes). He had inherited the frame from a Norton imported and supposedly it has never been used. It has a few minor scratches but certainly could be unused. There is no frame number or even drillings for the VIN plate, so I have no way of knowing the history.

I still ended up having to buy a bottom yoke, and I ended up painting the top one myself rather than paying to get it powder-coated. At least all lines up now. Just need to pay more money for new stanchions before I can fit the front wheel.

Talking of wheels:

Took a few attempts but I got there

Luckily the rims were in quite good nick and the hubs polished up nicely. I am waiting for a trueing jig before tightening the spokes. If I fail I can still get them done by a pro.

So the waiting game continues: tires & tubes ordered; wheel straightening jig; rear brake drum and spindle (was not included); and mostly - the motor back from the machine shop. They promised in two weeks now...

June Update

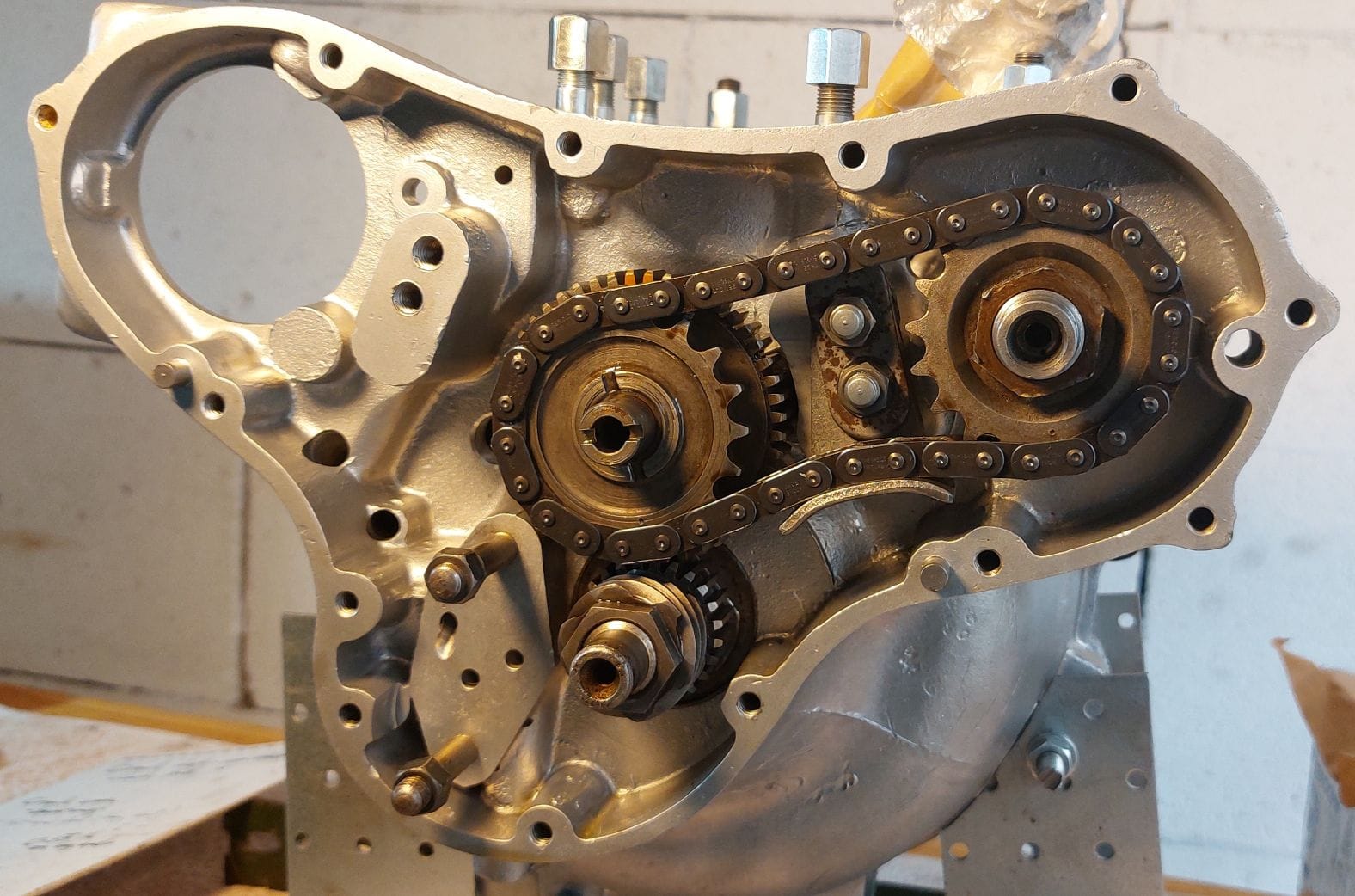

Boy, this is taking on a life of its own... I thought I was making progress having got the cranks case together: once only to find the camshaft wouldn't turn. Christian persuaded me to ditch the old breather system and drill a hole in the casing for a new breather on the timing side.

Put it together again after spending hours scraping of the 3-Bond sealant, only to find I had the crankshaft the wrong way round. Hours more scraping. Started on the timing side components and thought this was progress until I realised I hadn't put Loctite on the 2 nuts and also decided to renew the cam chain and tensioner. The chain is not in stock so another week's delay.

Old and new tensioner

I am also waiting for a second opinion on the state of my cylinder head. The Schleiferei cleaned and ground the valves but didn't keep note of which port they were from. They are quite pitted and at least one guide has a fair bit of play. The guides are rusty too. Then there is the corrosion and unevenness of the intakes. Not sure what to do about that. Hopefully Christian Sachslehner can answer my worries.

I tried a piston in the barrel and found it a very tight fit: had to beat it up and down with a wooden stick. Need advice on that too.

I got both tires on amazingly easily using my new levers, rim protectors, hair dryer and rubber grease. But then realised I hadn't ground down the spokes on the rear wheel so will need to take tire and tube out again, joy.

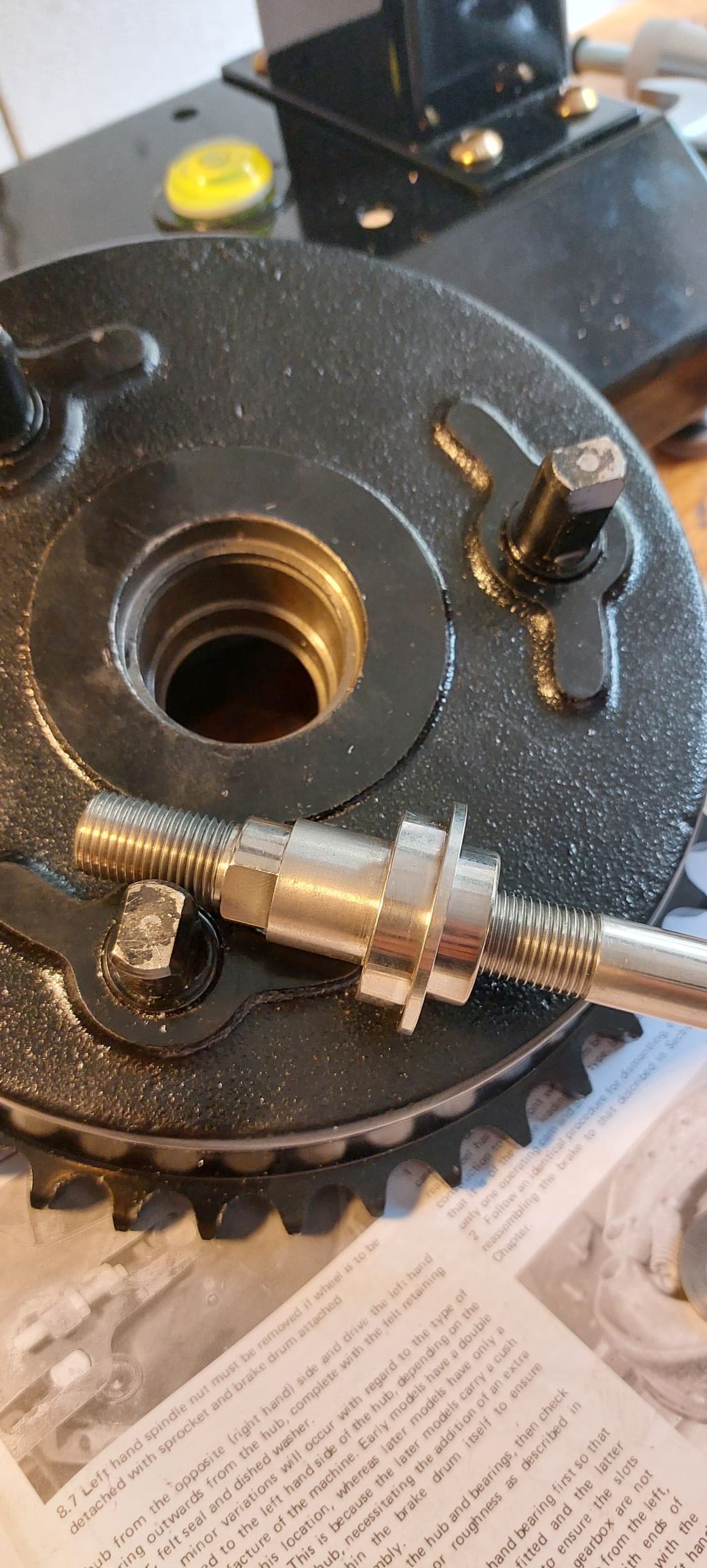

The dummy axle for the rear brake drum was the wrong size so was delayed a couple of weeks waiting for the right one from Holland.

Rear drum "dummy axle" was for pre-Commando. Delay

So here I am 8 months into the project and not even the engine rebuilt. I do however have a second garage so from Tuesday I can move the Mini and two other bikes out of the workshop and get my parts more organised.

I did buy new Amal Premiers for Norton 1 as it was only firing on one cylinder since its winter hibernation. Started immediately and runs well, though for almost €600 it bloody should.

September 2025

Finally some progress!

Finally got the head back from a Norton guy who put in new valve guides. Got all the rockers and bits in and installed it on the motor. With help from my daughter we spent almost 4 hours getting the damned thing in the frame...

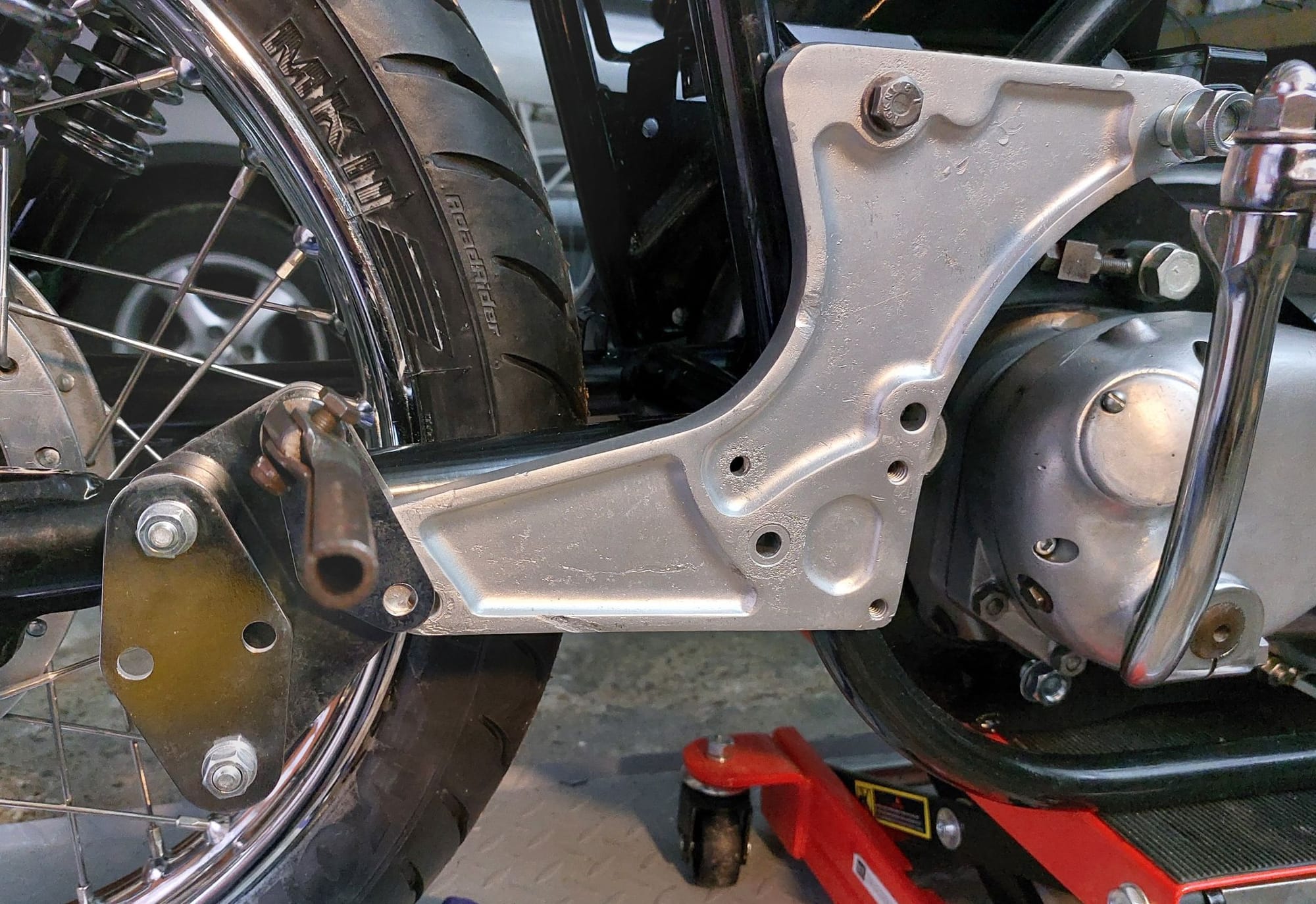

We lay the engine on the floor and put the frame over it. The main problem was lining up the bolt holes for the front engine mount. Had to stand the whole thing upright in order to do that.

Then I assumed I could simply slide the completed cradle, swing arm and gearbox into the frame and bolt it up. Nope. Had to remove the gearbox and the isolastics. Getting both of them back in was quite an issue only done by pivoting the motor on the one bolt. Ditto for the bottom cradle mounting bolt. I guess someone doing this regularly would need only 1/2 an hour. Next time.

Now I have started buying all the other bits, though the list does not seem to get shorter, nor the prices cheaper. Next I will tighten all the mounting bolts, put on the head steady and adjust the isolastics. Should be fun.

November 2025

Always 2 steps forward and one back. I work happily away until I get stuck - due to either lack of knowledge, ability, the correct part or something not working.

The fork sliders are a problem. They are worn unevenly inside so the suspension is sticky at best, or stuck at worst. I will eventually need new sliders but they are expensive.

The rear tyre has a bulge in it so will probably take it to a professional for fixing. I don't think it is the rim.

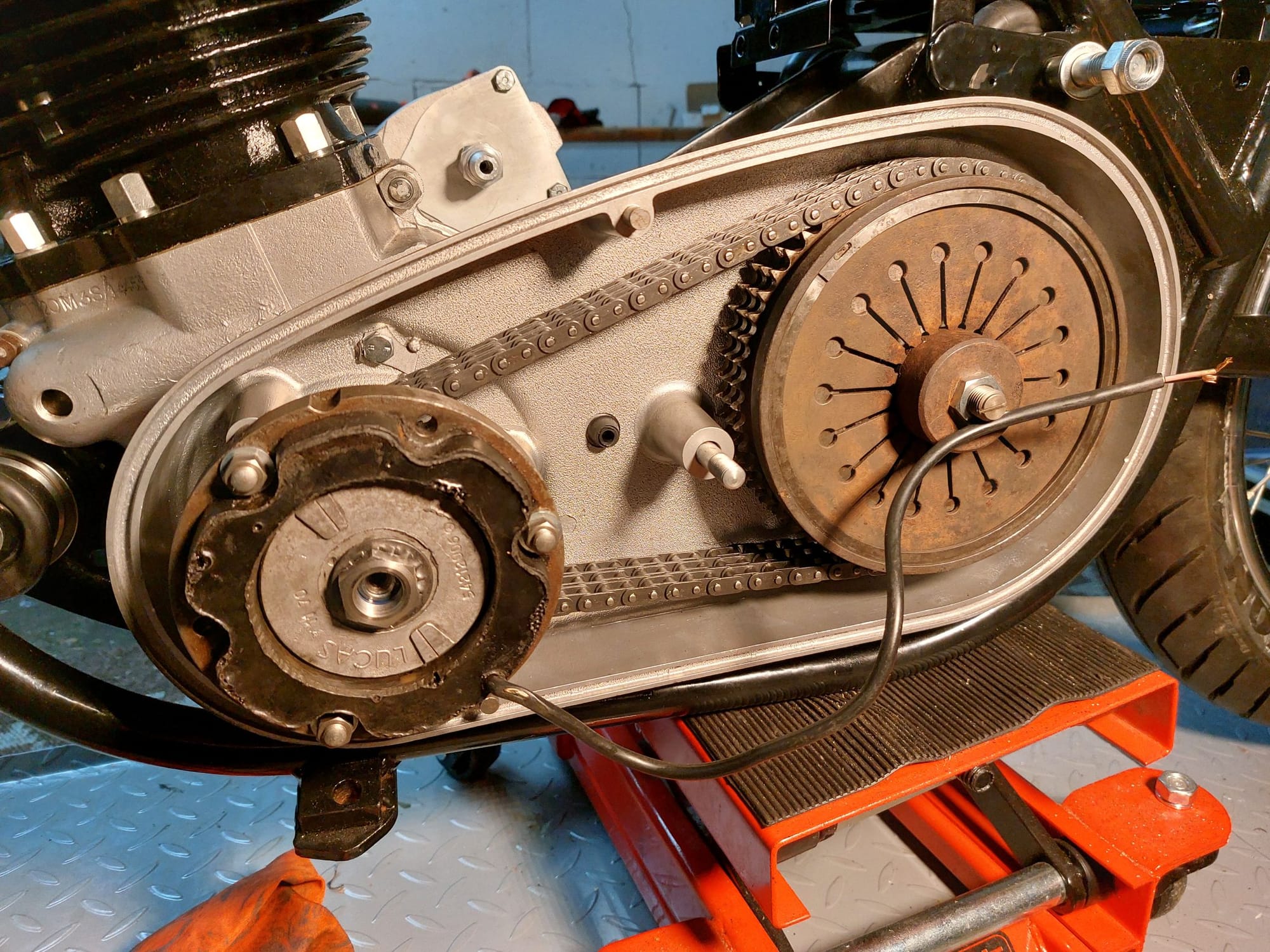

Had to replace the rusty clutch centre and bearing

Stamped the VIN plate and drilled holes in the frame for it. Primary side complete.

The rotor seems to be sitting a bit too far back in the stator, plus I don't even know if it works. But it's in place for now.

Was going to fit the new points cover that I bought but noticed the 2 old bolts are stripped inside the timing cover:

Working on z-plates and footrests but so many different bolts, studs, spacers and nuts required. Now ordered.

I was about to instal the mudguards I got with the bike but they are not the correct ones so I've had to order new for mucho more money.

Here's a list of things that were not correct and involved lots more money:

- mudguards

- rear brake drum (was for older bolt-up type of wheel)

- headlight lugs for some reason were 1cm too short.

- front wheel spindle was not correct one

I am currently awaiting various items including cables, electronic ignition etc from Wassel via Christian Sachslehner. The electrics will be a challenge.

December 2025

As usual going 2 steps forward and 1 back, though sometimes it's worse. I have both mudguards on, though had to drill holes in the rear one for all the fasteners. I am still waiting for a bracket for the rear mudguard and for spacers for the z-plates - with Norton Motors Deutschland having closed I need to rely on Mark Upham at British Only in order to avoid import duty and he doesn't stock everything.

Getting the oil tank in is a major fiddle. Plus all my oil leaked out. The outlet banjo bolt wasn't tight enough, and there was a bolt at the bottom of the timing side that was bottoming out so I couldn't tighten it enough. I've taken a cm off it and will see next time if oil is still seeping out.

The Wassell ignition has been a real pain: I had to send and grind lots of the circular space down before it would fit, and one of the holes that MiniSprint repaired for me was off a bit so I had to file down the corresponding ignition bolt slot. Finally got it in.

I am crap at crimping connections, so getting 2 bullet connectors on the cables took several tries. I've fitted the ignition box under the coil bracket with some 2-sided tape and a couple of cable ties. Not super professional but might hold.

I've got the Lucas switched apart and waiting for new parts and a polish.